Jewelry customization is a process in which the designer takes the customer’s requirements and combines the customer’s requirements with the designer’s understanding to create a unique piece of jewelry.

In this process, jewelry designers need to weigh the concept drawings with the user’s budget, design style, craftsmanship, cost, etc.

1.communication

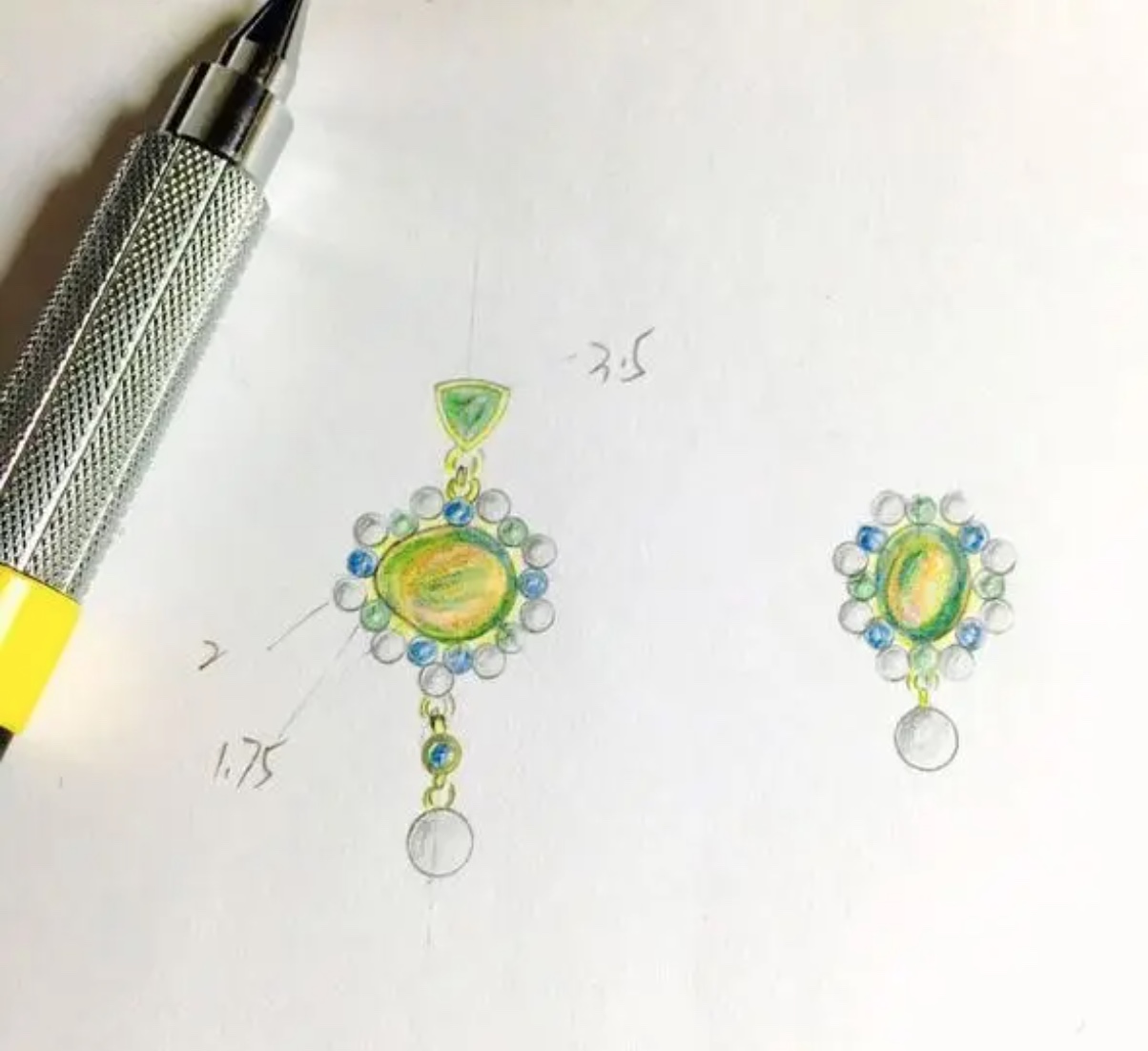

After the initial communication, the designer will provide the customer with a simple line drawing with multiple directions. The client selects or offers suggestions for revisions and then utilizes them as a blueprint for improvements and adjustments.

2.design

After deciding on a direction, the designer considers the color and cut of the stone to match the multi-directional inlay technique and creates a hand-drawn drawing using watercolor 1:1 based on the line drawing. In addition to showing the shape and structure, the hand-drawn drawing also shows the inlay technique and details for the pattern maker to create according to the drawing.

- Create a prototype version

There are two popular methods of prototyping, one of which is to design a prototype through 3D software.

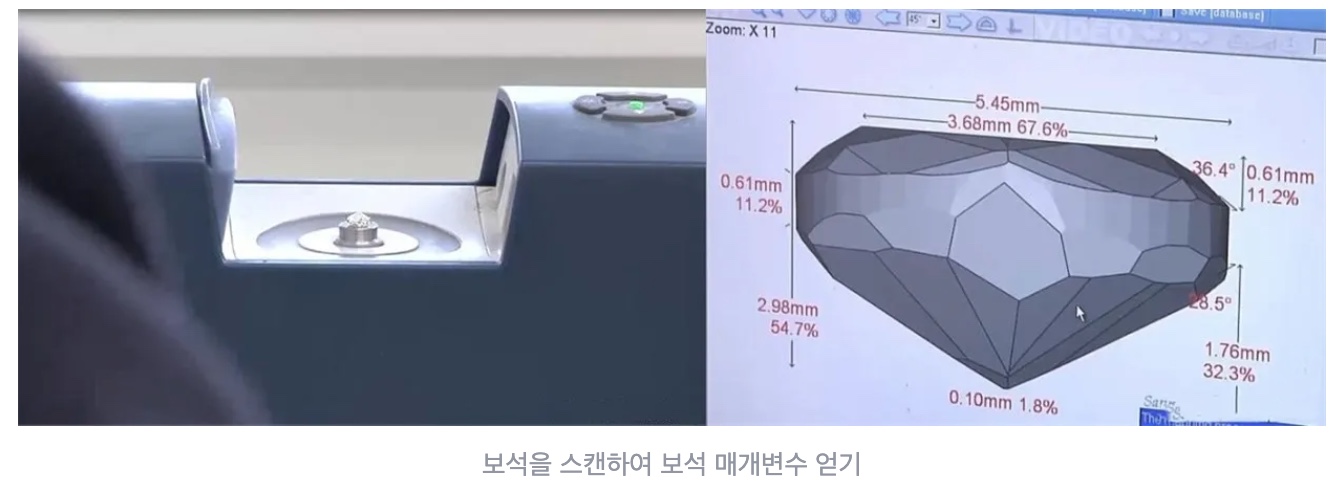

1). 3D scanner scans the annotation to get the exact size, facet distribution and 3D structure data.

2). The pattern maker uses 3-D software (jewelcad is commonly used) to create a model according to the design drawing.

3).The designed 3d model is output to 3d wax spray printer to produce the wax version.

Computerized prototyping can already produce wax models with a high degree of precision, but it has also greatly improved efficiency.

However, in fine jewelry customization, hand-carved wax has always been used to produce wax plates. Hand-carved wax has irreplaceable advantages in the production of human figures, animals, flowers, plants, etc. As they say, handmade objects have a soul.

In the process of manual wax carving, according to the design drawing, the matching stone position is drawn on the wax mold, and the stone position needs to be carved accordingly.

The cost of hand-carved wax is higher than computer-based carving because hand-carved wax requires high artistic skill and is a task that requires patience and attention.

4.Casting

Whether it is a 3D prototype or hand-carved wax, the resulting wax model must be converted into a precious metal casting through the lost wax method.

1). Sealing

For small pieces such as jewelry, wax trees are usually planted to turn wax molds into metal castings in batches.

When the prepared wax model is welded layer by layer in a certain order on a wax stick, a tree-like wax tree is finally obtained.

Weld the wax patterns as close together as possible so that they do not touch each other.

2). Fill with plaster

Place the planted wax tree and base into a stainless steel tube, slowly inject the plaster slurry, and leave it naturally for 6-12 hours until the plaster hardens.

3).baked plaster

The plaster mold is baked for the purpose of dewaxing, drying, and keeping warm for casting.

4). Pouring liquid gold

After the plaster mold is dry, melted gold water is poured into the nozzle.

5).Plaster mold blasting and cleaning

Since the plaster mold is in a high temperature state, it is necessary to take it out, leave it for a while, and put it in cold water to blast it, which will cause the plaster to explode due to shrinkage. At this time, take out the golden tree, shake off the large pieces of gypsum, soak it in 30% hydrofluoric acid for 10 minutes, then take it out, rinse and remove the remaining gypsum until the surface of the golden tree is clean.

6).Remove the casting

7).Cutting the casting

Cut off the ornaments on the golden tree one by one and wait for the next molding step.

5.Running the model

The molding is all done by hand, with a special calender knife sliding back and forth across the surface of the jewelry to correct and clean up any imperfections and give the casting a preliminary polish.

6.Choose matching gemstones

According to the jewelry design drawing, we will manually sort the gemstones, select the gemstones with suitable color,cut,size to prepare the inlay.

7.set the gemstones

The stone setter sets each diamond and gemstone by hand. It’s a technical job that needs to be done under dozens of magnifying glasses.

8.polishing,electroplating

Once the gemstone setting is complete, the metal surface and details need to be further polished. Some gemstones require surface electroplating.

9.cleaning

10.quality inspection

The final inspection of the appearance, structure, surface, etc. of the finished product, and if it is not suitable, it must be returned to the previous process to be remade.